(Integrated work package)

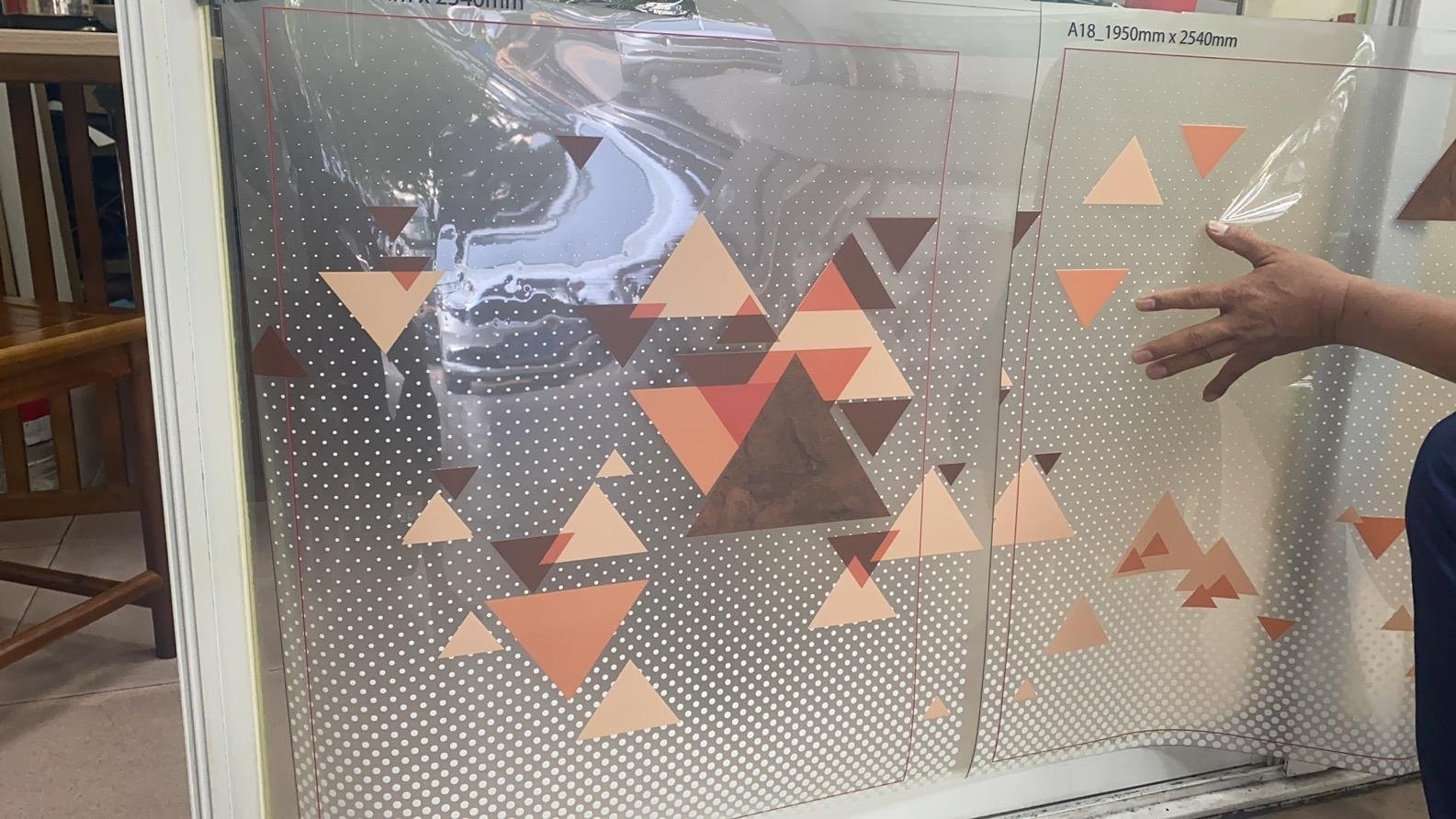

BB 3M construction, automotive insulation film, color changing film, invisible film, wood grain soft decorative film

Furniture renovation stickers self-adhesive wood grain stickers wallpaper veneer wardrobe cabinet wooden board wooden door desktop waterproof imitation wood

BB Film Engineering Company has been engaged in technology development and research for more than 20 years. According to the needs of different customers, it has developed two series of thermal insulation safety film products. One is a brand for high-quality household use, which is in stock. One is for high-quality industrial and commercial thermal insulation safety film products and wood grain wall stickers, thickened waterproof self-adhesive wood grain wallpaper, wood grain wall stickers, wall stickers, Boeing film floor stickers, cabinet furniture renovation, wood grain veneers, wood veneers, wood veneers. Skin

3D three-dimensional wood grain wall stickers, wood grain wallpaper, wood grain wall stickers, self-adhesive wall stickers

(BB Film Engineering Company) - 3M Authorized Film Approval Contractor. (Integrated work package)

Specializing in installing sun protection, heat insulation or explosion-proof glass films for homes and industrial and commercial enterprises, as well as interior decoration film services.

contact us

peter@bbfires.com

852-69318059

WeChat: 13714791523